American precision-style press brake punches are some of the best in the world, thanks to their high-quality construction and attention to detail. If you’re looking for a punch that can provide you with clean, precise cuts time after time, an American precision-style punch is definitely worth considering. This method is commonly used in the aerospace and medical industries, where the precision of measurements is very critical. In this write-up, we are going to provide a brief overview of how the American precision style works, why it is suitable for you, and what are its some of its prominent benefits.

Why American Precision Style?

So, what sets the American precision style apart from other types of press brake punches? A few key factors contribute to the superior quality of American precision-style press brake punches.

First and foremost, American precision-style press brake punches are made from high-quality materials. This ensures they can withstand years of heavy use without breaking down or damaging. Additionally, American precision-style press brake punches are designed for easy maintenance and repair. If something does go wrong, you can simply replace the part that is damaged rather than having to buy an entirely new punch.

Another factor that contributes to the superior quality of American precision-style press brake punches is their attention to detail. Every aspect of these punches is designed with precision in mind, which results in cleaner, more accurate cuts.

How American Precision Style Works?

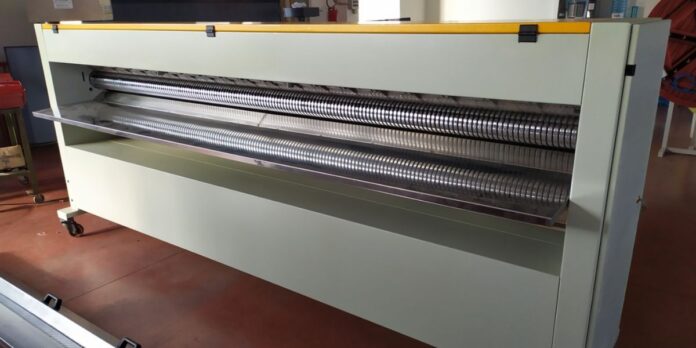

American precision style gets its name from the fact that it uses a press brake to create punches with very precise dimensions. A press brake is a machine that uses molds to shape metal into the desired shape. The molds are placed on either side of the metal, and then the machine presses the two sides together, forming the metal into the desired shape.

Benefits of American Precision Style

There are many benefits to using the American precision style, including the following:

Precision: As we mentioned above, one of the main benefits of this method is that it allows for very precise measurements. This is essential in industries like aerospace where even a small deviation can cause problems.

Complex shapes: Another benefit of using the American precision style is that it can be used to create complex shapes that would be difficult or impossible to create with other methods. This makes it ideal for creating parts with intricate designs.

Tight tolerances: Another benefit of using this method is that it allows for tight tolerances, which means parts can be made with precise dimensions. This is essential in industries like aerospace, where even the slightest deviation can cause problems.

Durable: Parts made with this method are also durable since they’re made from high-quality materials. This makes them ideal for use in applications where parts must withstand high temperatures or corrosive environments.

Conclusion

American precision style, also known as press brake punches, is a type of tooling used to create precision metal parts. This method is commonly used in the aerospace and medical industries, where precise measurements are critical. In this blog post, we’ve given you a brief overview of how the American precision style works and some of its benefits. If you’re in need of precision metal parts, consider using this method to get the best results.