The world is moving towards innovative living, and so is every industry. In the modeling and carving industry, CNC machining services play their part. These services have made multiple manufacturing parts much easier and more convenient. The models made through the CNC machining process are far better than the ones made through traditional methods and are sharper with more precise detailings for a better manufacturing experience.

An Introduction To CNC Machining

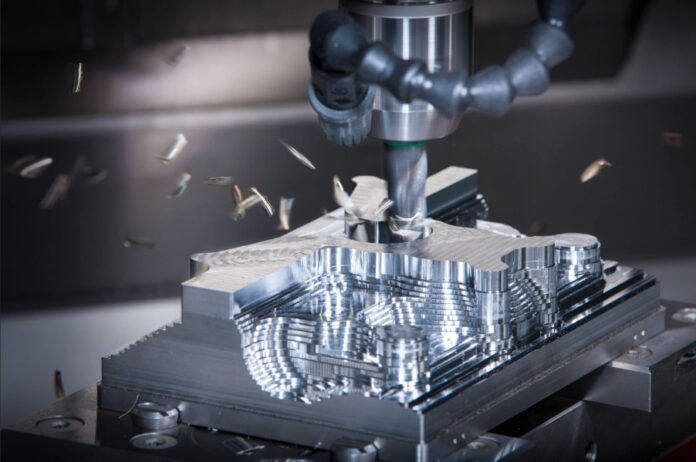

CNC is a precise modeling method controlled by computers. The process undertakes multiple materials, such as wood and aluminum. In the CNC machining process, a CNC machine removes the excess material from the stock piece and gives it the shape of the design. The machine is a time-saver, and cost-effective as only one person can operate it.

An Overview Of The CNC Machining Process

CNC/CAD designing companies use machines to produce a model. These models are made with a fundamental production process in which the designer produces a CAD design. The CAD model is then converted into a CNC design which the CNC machine can easily read. The CNC machine is prepared, and the operations are started to convert the stock piece into an organizational design.

How To Create A CAD Model Design

Have you ever thought of creating a CAD model or design? Yes, you can do the job at home. It is easy to create a design, but you need to know the basics first. You can also hire a CAD designer service to make the design. CAD is a 3D model or design created by computer software. There is an already available library of shapes and designs available in the model, which you can use to create a design. If you are a pro with 3D design software, it is easy to create the shapes yourself. If the model is too complex and has precise details, we recommend hiring a CAD design service provider. Remember, a good and precise design will always result in a detailed model.

How CNC Machine Produces Model Details

The CNC machine carries out multiple operations to focus on every detail of the model. The CNC drilling machine operation is used to make the cylindrically shaped parts of the model. The drilling part of the machine is mainly used to make aluminum machine parts and is used in aerospace and mechanical parts production with high precision. CNC milling is a process mainly used to cut models to shape them. This mechanism is primarily used in the making of 3D models. The third process is 3D turning. With the 3D turning process, it is easy to detail the hollow parts of the model. This mechanism is mainly used to cut the parts capable of turning in any machine.

Conclusion

CNC is the latest form of making models and exact technology. There is no match of the machine in precision. It is better to go for a CNC machine servicing than to waste money on a traditional modeling method that needs to be more precise and detailed. Move towards innovation to get the best results. 3ERP is a company with CNC machining experts to help you get the best results for models.